PRODUCTS

- Woodworking Planer>

- Sanding Machine Series>

- Saw Series>

- Press Machine>

- Finger Joint Machine>

- Brush Sander Series

- Edge Bander>

- Wood Boring Machine>

- CNC Router

- Vacuum Membrane Press>

- Woodworking Thicknesser

- Spindle Moulder

- Mortising Machine

- Profile Wrapping Machine

- Knife Grinder Machine

- Planer and Sander Machine

- Wire Drawing Machine

- Paint Finishing System

- Air Compressor

- Ungrouped

Product recommended

Hotline:

86-532-67703247

Email: mike@sinosteeler.com

Phone: 86-18615326395

Address: Yanjialing Industrial Park, Tongji Office, Jimo, Qingdao, Shandong, China

New Disc type tools change CNC ROUTER STR1325S-ATC cnc router

- Characters:A.The Features of this machine:1.The bed is made

- Hotline: 86-532-67703247

- Fax: 86-532-68067870

- Email:mike@sinosteeler.com

Detail

Contact Us

Characters:

A.The Features of this machine:

1.The bed is made of strong steel tube structure and it is analyzed and designed with Heavy Duty and Strong

Structure which relieves stress and makes working table more steady.

2.Locating bearing, ball screw, linear slide way are controlled by the control system of bed lathe and they are also maintained by the Auto-lubrication system.

3.Enlarged X and Y axis’ stroke that enable to make big size nonmetal material; to equip with Yaskawa servo

motors , 9KW HSD shaft spindle (made in Italy) (optional).

4.The automatic tool changing system which contains 8 pieces of cutting tools is controlled by CNC ( Syntec

Control system). The tools can be changed very quickly and reliably.

5.The worktable is equipped with vacuum system which can absorb different kinds of nonmetal materials.

6. The automatic changing tool system is optional.The machine own its patent for its patent department.

7.The machine gantry and the arms is together without welding, this is for avoiding shaking when the machine work long time. Thus it can guarantee the machine resolution and avoid shaking.

8.The Square rails and Ball screw is all big model to guarantee its long time usage and resolution for heavy

cutting.

9.The machine traveling speed can reach 45000mm/min, processing speed can reach 25000mm/m.

Application:

This machine is suitable for engraving and cutting PVC, MDF,ACP or ACM, inox sheets, acrylic, density board,

door, computer table, furniture, rosewood nonmetal materials and nonferrous metals such as copper and

aluminum.

Technical Parameter:

1 | Max. engraving area | 1300*2500*220mm |

2 | Acceptable material thickness | 220mm |

3 | Working table | T-slot and Vacuum Combined Working Table |

4 | Vacuum pump | / |

5 | Working table size | 1300mm*2500mm |

6 | Processing resolution | ±0.002mm |

7 | Reposition resolution | ±0.002mm |

8 | Spindle motor | 9KW Original HSD Air Cooling (Auto Changer Spindle) |

9 | Spindle rotating speed | 24000rpm |

10 | Transmitting system | X\Y axis Rack and Opinion+ Square guide; Z axis ball screw+ Square guide+ Cylinder |

11 | Engraving tools | ¢3.175mm/¢6mm/¢12.7mm |

12 | Driving motor | Yaskawa Servo Motors+ Original Yaskawa Servo Drivers(Original Japan Brand) |

13 | Power consumption | 4.5KW(Without Spindle) |

14 | Empty Traveling Speed | ≥45000mm/min |

15 | Processing Speed | ≥25000mm/min |

16 | Tool Storage | 8 Pieces |

17 | Control system | Syntec Control System(Original Brand) |

18 | Software | Type3, Artcam, Ucancam, Caxa,Mastercam, UG |

19 | Format | G code |

20 | Voltage | 3 Phase 220V, 60HZ |

21 | Surroundings | Temperature: 0-45℃; humidity:30%-75% |

22 | Net Weight | 2150KG |

23 | Packing Size | 3600mm*2200mm*2050mm |

Product Details:

The parts:

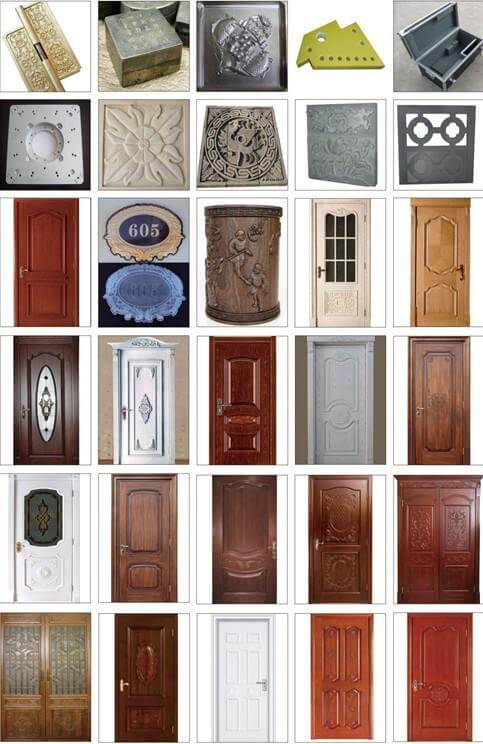

The finish products:

The finish products:

Packaging & Shipping:

1.The Packaging Details:Stretch film with wooden case or as your request!

2.Shipping:We have rich experience in exporting machines to the world and can supply all kinds of different shipping terms!

3.Timely delivery and transportation

Our Services:

1.Good after-sale Services is our strength

1) The machine guarantee is 12 months.

2) 24 hours technical support by email or calling.

3) Friendly English version manual and operation video CD disc.

4)Our engineers can provide services to overseas.

2.Main Market

Which have been exported to a lot of country and Regions . Such as Europe , Russia, Southeast Asia . Middle East . North America and south America , Australia .

3.Sample Service:

If you want to test the performance of machine ,we can sent sample to you with cost offer .

4.Customized Service:

Our factory has been specialized in producing woodworking machines for over 33 years .We have very high research and development capabilities to meet the requirements of custom.

5.We have years of manufacturing woodworking machine,OEM and ODM service available.

Company Information:

Qingdao Steeler woodworking machinery co.,ltd is the professional production of various kinds of sanding machine,polishing machine and other mechanical equipment manufacturers.The company produced sanding machine which is a combination of Germany,Italy,Taiwan's good mechanical properties,structure and the advanced polishing machine not only draw lessons from the foreign advanced technology,and highlights the Steeler people development innovation,enterprising spirit,continuous research and development to adapt to the market,make our polishing machine series equipment industry's leading edge products.

We have already approved the ISO9000 International quality system certification and the main products through the national certification,access to the national key new products,high-tech products such as the honorary title,by the Chinese enterprise brand quality committee awarded the "National quality credit AAA grade credit enterprise"brand,the company products are sold well all over the world.

A strong R&D team,strong processing power,the reliable quality assurance,strict testing means make the company to win the trust of users.

Rich experience,sophisticated design,advanced manufacturing technology,as well as relevant to the users'communication,make the company continuously introduced to adapt to the market,meet the users of the new product.Quality,efficiency,service,integrity,modest is the goal of the Steeler People !