PRODUCTS

- Woodworking Planer>

- Sanding Machine Series>

- Saw Series>

- Press Machine>

- Finger Joint Machine>

- Brush Sander Series

- Edge Bander>

- Wood Boring Machine>

- CNC Router

- Vacuum Membrane Press>

- Woodworking Thicknesser

- Spindle Moulder

- Mortising Machine

- Profile Wrapping Machine

- Knife Grinder Machine

- Planer and Sander Machine

- Wire Drawing Machine

- Paint Finishing System

- Air Compressor

- Ungrouped

Product recommended

Hotline:

86-532-67703247

Email: mike@sinosteeler.com

Phone: 86-18615326395

Address: Yanjialing Industrial Park, Tongji Office, Jimo, Qingdao, Shandong, China

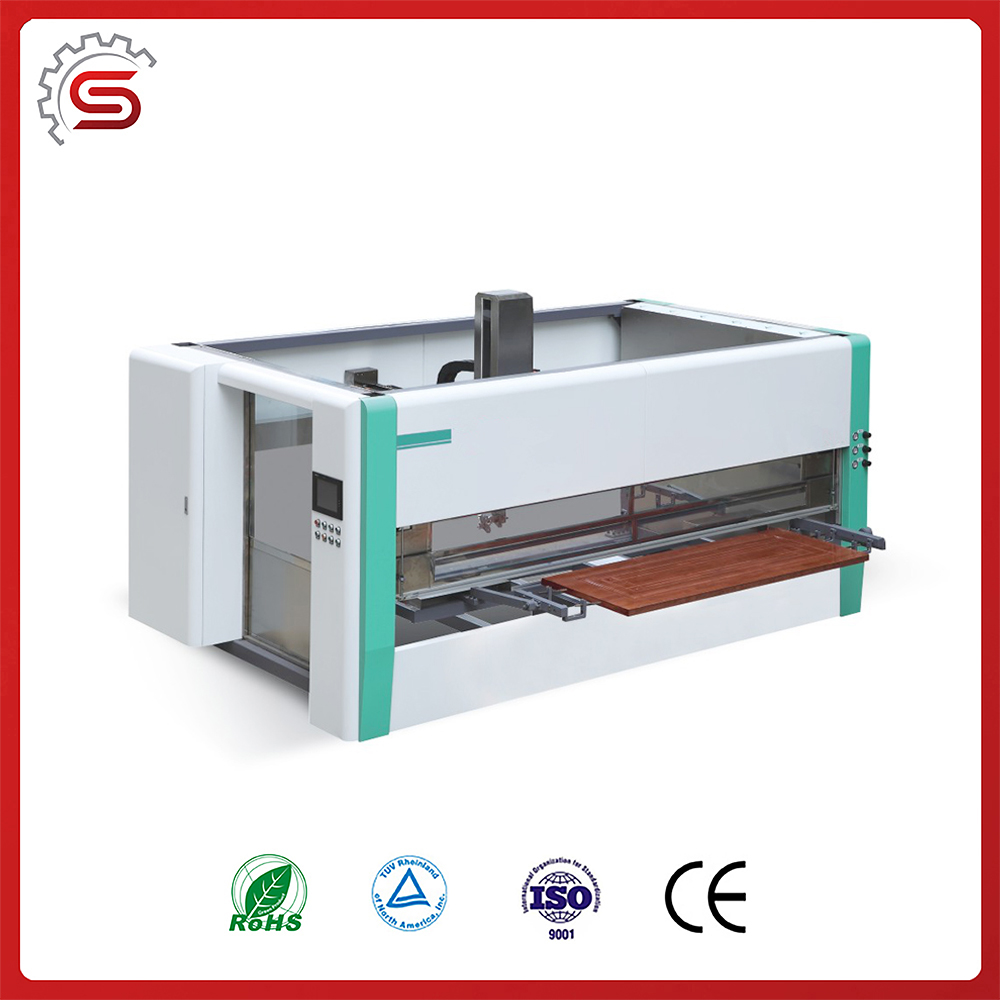

Good price machine SPR1300 Automatic Spraying Machine with high abraasion

- Product DescriptionTechnical parameter:MODELSPR1300Max. spraying width1300mmMax. thickness of w

- Hotline: 86-532-67703247

- Fax: 86-532-68067870

- Email:mike@sinosteeler.com

Detail

Contact Us

Product Description

Technical parameter:

MODEL | SPR1300 |

Max. spraying width | 1300mm |

Max. thickness of work piece | 100mm |

Max. feeding speed | 5.2m/min |

Spraying gun | 8pcs |

Air pressure | 0.5-0.8Mpa |

Total power | 14.5kw |

Figure dimension | 4800X67000X2500mm |

Weight | 2000Kg |

Detail:

Feature:

SPM series automatic spraying machine has been designed to achieve high quality finishing on any kinds of surface. It allows high production performance and the reclaim system in compliance with the strictest environmental neds and regulation.

♦Equipped with high precision color touch screen, it is very simple. This guarantees a completely automatic management of different working recipes that optimizes the machine performances.

♦All working parameters can be easily set and saved to be reused.

♦In case of malfunctions, a diagnostic program indicates proper error messages to help the troubleshooting.

Workpiece runs under scan, this allows a very reliable detection of the section that has to be painted.

♦An innovative automatic cleaning and recovery system located on the lower part of the spraying zone, allows total recovey of the sprayed product deposited on the feeding belt.

♦The transport belt is made of special material, with high abraasion and chemical eroding resistant. It is easy to be changed and cleaned.

♦It needs little thinner to clean the belt. The life of the belt can be prolong by the scientific design.

♦The 2 spraying units can equipped 8 spraying guns which is connected to one or more product circuits according to requirements.

♦The spraying guns are very easy to install, adjust and replace.

♦Dry filtrate system which is on the both sides of the spraying zone, can detain the pollute particles and exhaudt clean air.

♦It is available a display showing when the filters are saturate and have to be cleaned and replaced.

♦Double filter system ensured that the air which enter the closed room keep clean.

♦The air-pressblowers are installed at the air inlet to keep the paint reek within limits.

♦The blower with large horsepower is installed at the exit to fasten the waste gas in the painting room and reduce its staying time in the room.

Each spraying gun has a press valve independently to get exact pressure.

Packaging & Shipping

1.Packing details: Stretch film with wooden case or as your request.

2.Shipping:We have rich experience in exporting machines to the world and can supply all kinds of different

shipping terms.

3.Timely delivery and transportation

After-Sales Service

1.Good after-sale Services is our Superiority

1) The machine guarantee is 12 months.

2) 24 hours technical support by email or calling.

3) Friendly English version manual and operation video CD disc.

4) Oversea engineer after-sale service is available.

2.Main market

Our products has been exported to all over the word, including North America, EU countries, Austrilia, Southeast Asia, Africa and Latin America.

3.Sample Service

If you want to test the performance of machine ,we can sent sample to you with cost offer.

4.Customized Service

Our factory has been specialized in producing woodworking machines for over 33 years .We have very high research and development capabilities to meet the requirements of custom.

5.We have years of manufacturing woodworking machine, OEM and ODM service are available.

Our Customer Visit

Company Information

Qingdao Steeler woodworking machinery co.,ltd is the professional production of various kinds of sanding machine,polishing machine and other mechanical equipment manufacturers.

The company produced sanding machine which is a combination of Germany,Italy,Taiwan's

good mechanical properties,structure and the advanced polishing machine not only draw lessons from the foreign advanced technology,and highlights the Steeler people development innovation,enterprising spirit,continuous research and development to adapt to the market,make our polishing machine series equipment industry's leading edge products.

We have already approved the ISO9000 International quality system certification and the main products through the national certification,access to the national key new products,high-tech products such as the honorary title,by the Chinese enterprise brand quality committee awarded

the "National quality credit AAA grade credit enterprise"brand,the company products are sold well all over theworld.

A strong R&D team,strong processing power,the reliable quality assurance,strict testing means

make the company to win the trust of users.

Rich experience,sophisticated design,advanced manufacturing technology,as well as relevant to the users'communication,make the company continuously introduced to adapt to the market,meet theusers of the new product.Quality,efficiency,service,integrity,modest is the goal of the Steeler People!

FAQ

1) Q: What's the MOQ?

A: MOQ is one set.

2) Q: Provide custom machine Yes or No?

A: Yes. We can provide custom machine for clients.

3) Q: What's the payment terms?

A: T/T 30% in advance and balance before shipment or by negotiation.

4) Q: Are you factory or trade company?

A: We are factory and trade company.

5) Q: How long is the warranty period?

A: One year warranty period except the quick-wear parts.

6) Q: Do you have professional engineers?

A: Yes. We have professional engineers and designers. We can provide OEM products.