PRODUCTS

- Woodworking Planer>

- Sanding Machine Series>

- Saw Series>

- Press Machine>

- Finger Joint Machine>

- Brush Sander Series

- Edge Bander>

- Wood Boring Machine>

- CNC Router

- Vacuum Membrane Press>

- Woodworking Thicknesser

- Spindle Moulder

- Mortising Machine

- Profile Wrapping Machine

- Knife Grinder Machine

- Planer and Sander Machine

- Wire Drawing Machine

- Paint Finishing System

- Air Compressor

- Ungrouped

Product recommended

Hotline:

86-532-67703247

Email: mike@sinosteeler.com

Phone: 86-18615326395

Address: Yanjialing Industrial Park, Tongji Office, Jimo, Qingdao, Shandong, China

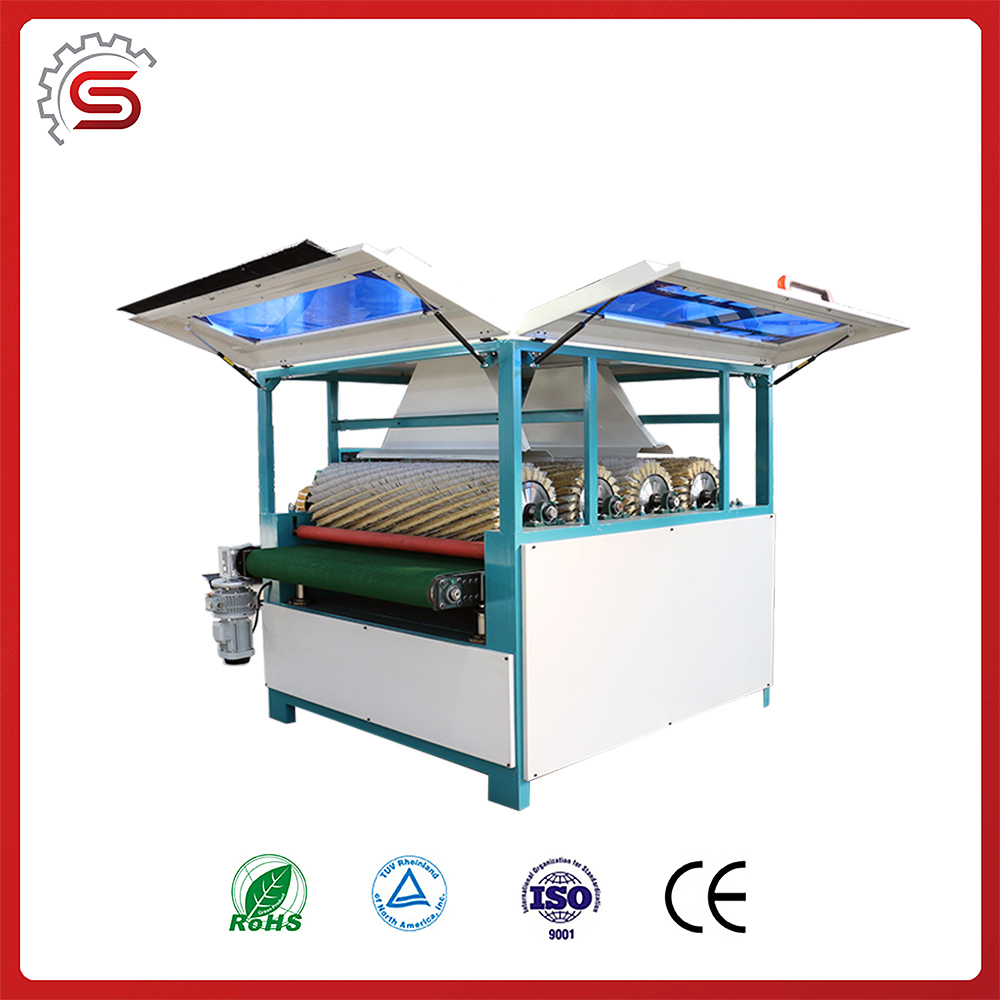

STR1300R-R-R-R drum sander for furniture Drum sander

- Technical Parameter:Model &n

- Hotline: 86-532-67703247

- Fax: 86-532-68067870

- Email:mike@sinosteeler.com

Detail

Contact Us

Technical Parameter:

Model | STR1300R-R-R-R |

Max working width | 1300mm |

Max working thickness | 120mm |

Roller diameter | 280mm |

Main motor | 2.2kw |

Lift motor | 0.37kw |

Conveyor motor | 0.37kw |

Size | 2600*2000*1850mm |

Application:

This wood panel sanding machine is suitable for all kinds of solid wood, MDF, leather panels affixed to the rules of surface material, shaped face, flat and curved surfaces of coarse and fine sanding, grinding, polishing.

Feature:

1.Suit for sanding cabinet door,sliding door and other furniture.

2. The speed of feeding and thickness are sufficiently adjustable.

3.This machine with high quality and stability is easy to control.

4. It can improve efficiency and reduce cost.

Advantage:

1. Use cylinder pressure to save time for customers more conveniently and quickly. Only traditional weight-reduction methods can be used.

2. Imported bearings and motors are used to ensure the stability and durability of the equipment. It also meets the precise requirements for its workpieces.

3, frequency control, soft start, soft stop, low impact, reduce workpiece damage.

4. With high-precision shaving device, it can ensure the stability of some workpieces with high precision in batch processing, which greatly saves time.

5. Reduce the grinding time, save the cost of consumables, and meet the requirements of the environment.